Coiled tube heat exchangers for cooling in tunnelling and mining

Heat exchangers for dusty and aggressive air conditions

WAT coiled tube heat exchangers are air/water heat exchangers that are designed in particular for application in dusty and aggressive air conditions. These heat exchangers are characterized especially by their positive system features:

- High heat transition coefficient

- Low pressure loss

- Robust design for underground application

- Trouble-free operation with minimal dust deposit

- Easy maintenance through fast cleaning

- Water-side operating pressure up to 63 bar

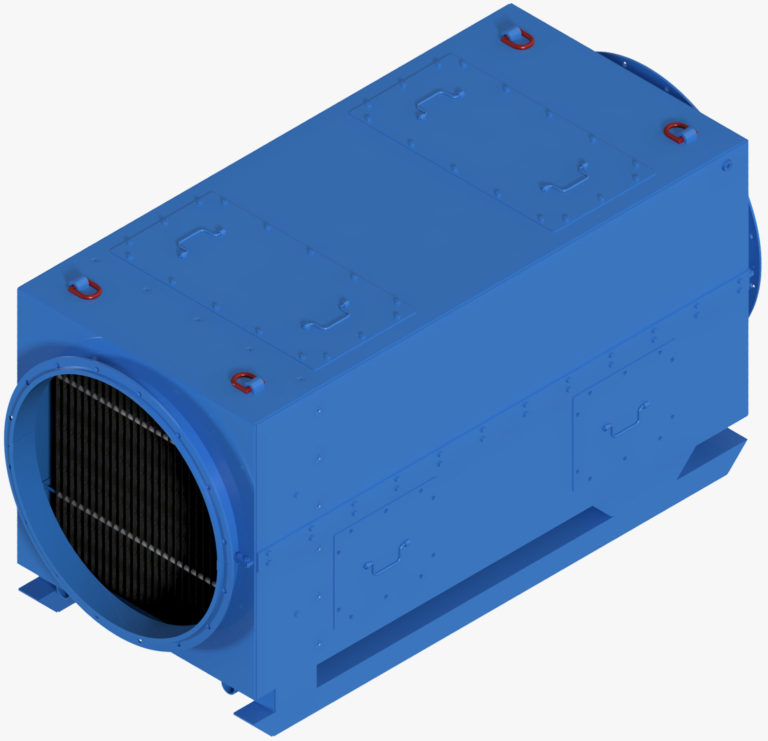

Air-Cooler

type RWK and SPK

Your benefits:

WAT air-coolers can be used everywhere, where specific high requirements are imposed on air-cooling, e.g. for application in underground roads or long walls as well as on a TBM’s back-up system.

- Heat exchangers with cooling capacity from 25 kW up to 2,000 kW

- Air/water heat exchangers for application at underground or on a TBM

- Water-side operating pressure up to 63 bar

- Explosion-proof design (ATEX group I Category M2 for mining)

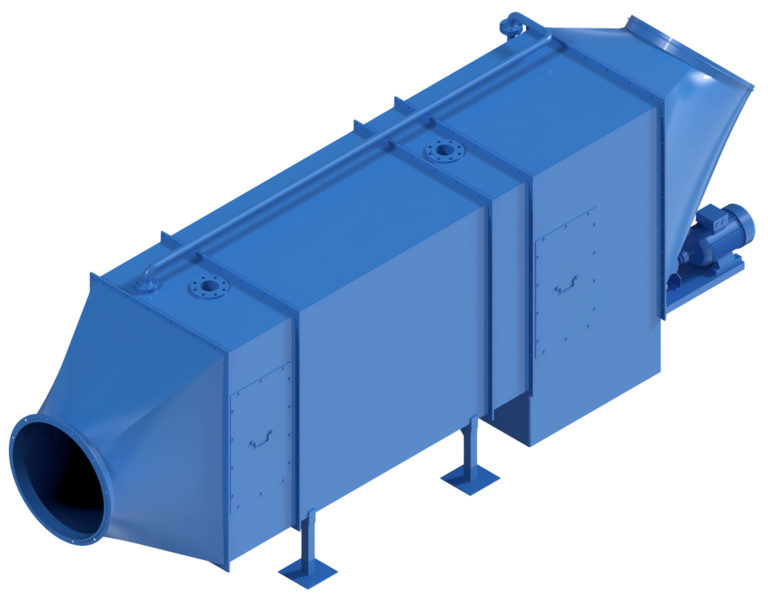

Re-Cooler

type RK

Your benefits:

WAT re-coolers are especially used, when only an underground re-cooling by air is possible and high requirements on re-cooling are imposed because of the air conditions.

- Heat exchangers with cooling capacity from 100 kW up to 1,500 kW

- Underground evaporative cooling tower (constant water supply necessary)

- Water-side operating pressure up to 63 bar

- Explosion-proof design (ATEX group I Category M2 for mining)